Essential Safety Tips: Understanding Different Grades of Anchor Chain and Their Purpose

Choosing the right chain for your needs

There are various grades of steel chains for different uses. The choice of grade depends on the application and the amount of weight or force it will endure.

Below are typical uses for different grades of steel chains and the reasons why?

It includes the risks of choosing the wrong grades and the danger of hydrogen embrittlement in chains grade 80 and higher.

Grade 30 Steel Chain:

People commonly use Grade 30 steel chains, also known as Grade L, for light to moderate loads. These loads include towing, logging, and securing loads on trucks and trailers.

Grade 30 chains are affordable and suitable for tasks that require strength and durability, but not extreme levels.

Grade 43 Steel Chain:

The agriculture, marine, and construction industries commonly use grade 43 chains when they need more strength and durability.

Grade 43 chains are stronger and more durable than Grade 30 chains, so they are good for handling moderate loads.

Grade 70 Steel Chain:

People mainly use Grade 70 chains in transportation and towing, especially for securing heavy loads on trailers and truck tie-downs. Grade 70 chains are stronger and can handle heavier loads. They are good for tasks that need more strength and can carry bigger weights.

Grade 80 Steel Chain:

People often use grade 80 chains for lifting and rigging in construction and industrial settings.

Grade 80 chains are strong and light, made for heavy lifting. Safety and reliability are very important.

Grade 100 Steel Chain:

We use grade 100 chains for tough lifting and rigging tasks, such as oil rigs, heavy machinery, and construction. Grade 100 chains exhibit great strength and durability, making them ideal for critical tasks that require uncompromising safety.

WARNING: The Dangers of Incorrect Chain Choice

Hydrogen Embrittlement in Grade 80 and above:

This occurs when hydrogen atoms enter steel. This causes the steel to become weak and easily prone to breaking. In fact, it can break with less force than expected. Stronger chains (Grade 80 and above) are more likely to become brittle from hydrogen. This can happen if the manufacturing process does not plate or clean the chain correctly. Additionally, exposure to hydrogen in environments such as acid, salt water, high humidity, or temperature changes can also lead to brittleness.

To avoid hydrogen embrittlement, it's important to follow correct manufacturing, handling, and maintenance methods. This includes avoiding corrosive substances and keeping chains dry and clean.

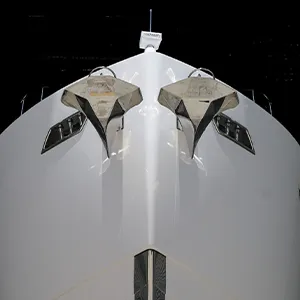

Higher grade Chains should be tested regularly by a recognised testing body to ensure safe operation. Grade 80/100 is NOT recommended as anchor chain.

Using the wrong steel chain can cause serious problems like property damage, injuries, or even death.

Using a weak chain can cause it to break. Using a heavy anchor chain may be unnecessary, subject to hydrogen embrittlement and expensive.

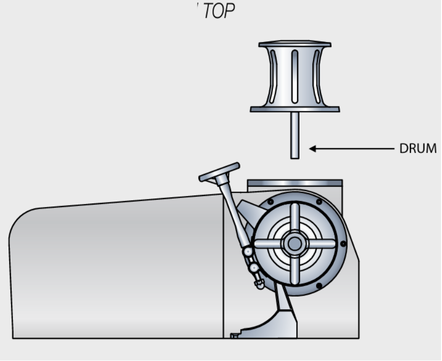

In summary, selecting the right grade of steel chain is critical to ensure safety and performance in all chain applications. In future blogs, we will discuss how to find the right chain length for boat anchors. This will include determining the additional length required for the anchor chain locker.