Galvanized marine anchor chain is a type of chain that is specially designed for use in marine environments. It is made of Carbon steel or Alloy Steel and is coated with a layer of zinc to protect it from rust and corrosion. The benefits of using galvanized marine anchor chain include it's resistance to corrosion, durability and strength. It is also cost-effective and easy to maintain.

There are two main types of galvanized marine chains: Carbon Steel (Grade L / Grade 30) and Alloy Steel chains, (typically Grade 40 to Grade 45) normally hot-dipped galvanized. Hot-dipped galvanized chains are more durable and have a thicker layer of zinc coating. Galvanised chain comes in many different sizes such as 8mm short link anchor chain, 10mm short link anchor chain and 13mm short link anchor chain.

The size of the galvanized marine anchor chain you choose depends on the size of your boat and the conditions you will be anchoring in. The size of anchor chain is usually specified by the boat manufacturer and is worked out by a Marine architect.

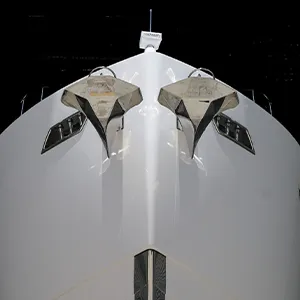

The length of anchor chain is determined by where the boat will be operating and the depth and size of the anchor locker. If the vessel is only operating in inland or sheltered coastal waters, you won’t need as much as a vessel operating offshore/traveling around the coast or overseas. When deciding what length of chain to get, always consider the worst scenario. Should you get caught in bad weather you will need to put a lot more chain out then normal anchoring conditions.

To maintain your galvanized marine anchor chain, you should rinse it with fresh water as often as possible (after each use or whenever you have access to fresh water). Chain should be end for ended about every 12months, this allows the chain to wear evenly at each end. The anchor locker should be well drained and cleaned regularly to prevent the chain sitting in wet sand and mud at the bottom of the anchor locker.

The lifespan of a galvanized marine anchor chain depends on the quality of the chain, how often it is used and how well it is maintained. Generally, a well-maintained galvanized marine anchor chain can last for many years.

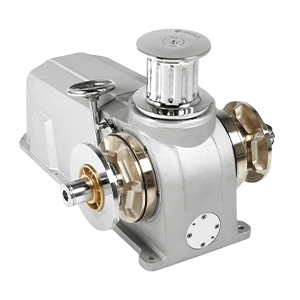

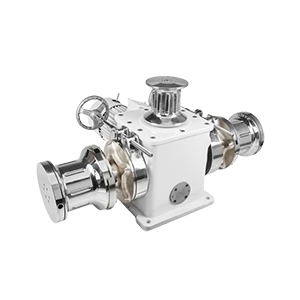

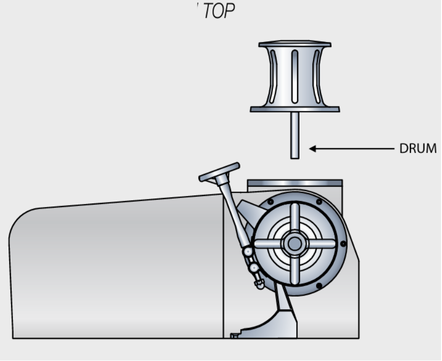

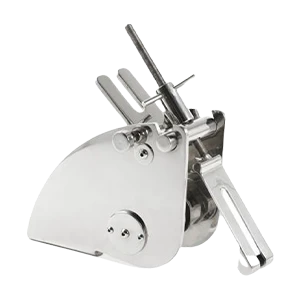

There are many types of galvanized anchor chains and stainless steel chain available around the world. Different types of marine chain have different measurements. It is important to make sure you select the size and type of chain that will fit the Gypsy on your windlass. There will be a marking on your Gypsy, typically a code that will determine the size and type/types of chain you can use. The code will need to be checked with information provided by the windlass manufacturer.

Chain is often manufactured by or for lifting companies. Often these companies provide low grade carbon steel lifting chain as Anchor chain. These are usually marked grade L or Grade 30 and usually have a thinner Galvanized coating between 35 and 55 micron thickness. Marine Chain should be between Grade 40 and Grade 45. These chains are alloy steel, they are harder, approximately 50% stronger and normally have a galvanised coating of around 85 microns. Marine chain between Grade 40 and 45 will usually last longer because it is stronger so wont stretch as easily and is harder so wont wear as easily as Grade L /Grade 30 chain.

Anchor chain should be stamped with identifying marking of the company supplying the chain. It also should be stamped with the Grade of chain. Example: OMC and G43 or OMC G43. The chain should come with a test certificate as this is often required by insurance companies. There is a lot of cheap chain sold for anchoring without markings or test certificates. Often the link welds are not a good standard, and you don’t know what strength the chain is or if it is calibrated to the right standard.

The Short answer to this question is NO. Old anchor chain that you may be considering to re-galvanise has been used for some time and is showing signs of wear or rust, will most likely be stretched and worn in the links. Stretched and worn links wont sit well in the windlass gypsy and will cause your gypsy to wear out prematurely (Gypsy’s are often more expensive than new chain). The main reason you shouldn’t re-galvanise your chain is that the process puts your chain through another heat process, so your chain is no longer a tested chain and will not have the same strength.

Chain can be joined provided the joining link is of the same material, is tested to the same braking load and will run through your gypsy. A lot of Marine supply companies have stainless steel joining links for sale. These links normally are not tested and when they are joined to galvanised anchor chain instead of stainless steel chain. The two dissimilar metals together cause electrolysis and accelerated corrosion causing that section of chain to have the weakest link.