Preventing Deterioration of Your Galvanized Anchor Chain

When you’re anchoring your boat, it’s easy to focus on the basics: dropping the anchor, securing it to the seabed, and ensuring the vessel is held in place. However, the materials that make up your anchoring system—particularly marine anchor chain—can be exposed to a variety of environmental factors that affect their longevity and performance. One of the most insidious threats to marine chain, especially if it’s galvanized, is electrolysis, a process that can lead to corrosion and premature degradation. In this post, we'll take a closer look at galvanized anchor chains, what electrolysis is, and how it can affect your equipment while your boat is anchored.

What is Electrolysis?

Electrolysis is a chemical reaction that occurs when an electrical current passes through a conductive material, such as water, and causes the material to break down. In the case of an anchor chain, electrolysis typically occurs when electrical current from a boat’s electrical system (such as from the DC wiring or stray current) flows through the water and into the chain, causing the metal to corrode. The process is often referred to as 'galvanic corrosion'. At its core, electrolysis is a result of the difference in electrical potential between two metals in contact with an electrolyte, like seawater. This can be exacerbated by the presence of dissimilar metals (such as a galvanised steel chain, which is coated with zinc, in contact with copper or bronze components). The electrical current running through the water can cause ions to be stripped from the chain, leading to the degradation of the zinc coating and eventually to the underlying steel of boating chains.

Galvanized Anchor Chains: What You Need to Know

Galvanization is a protective coating applied to steel anchor chains to guard against corrosion, which is particularly important for vessels in saltwater environments. It is an anchor chain protector.The process involves coating the steel with a thin layer of zinc, which offers sacrificial protection to thechain. If corrosion starts, the zinc is eaten away first, leaving the underlying steel safe.

However, galvanized coatings are not impervious to damage. Over time, if the zinc coating is compromised due to abrasion, excessive wear, or environmental factors, the underlying steel begins to rust. Electrolysis can exacerbate this process, stripping away the protective zinc layer faster than normal wear and tear would cause on its own.

How Electrolysis Affects the Anchor Chain

When electrolysis affects a galvanized anchor chain, it typically does so in one of two ways:

1. Corrosion of the Zinc Coating

The zinc coating on galvanized chains provides an essential barrier to corrosion. However, when an electrical current flows through the chain, the zinc can be sacrificed in the electrochemical reaction, leading to premature corrosion of the galvanized surface. Over time, this can expose the steel underneath, making the chain more susceptible to rust and weakening its strength.

2. Corrosion of the Chain Itself

As the zinc is stripped away due to electrolysis, the anchor chain’s steel core becomes more vulnerable to rust and corrosion. This can lead to pitting, structural degradation, and a reduction in the chain’s overall lifespan. In some severe cases, the chain may even break under load due to weakened structural integrity, resulting in an anchor chain fail.

Sources of Electrolysis in Anchoring Systems

Electrolysis is more likely to occur in specific situations, particularly when the boat is at anchor. Common sources of electrical current that can lead to electrolysis include:

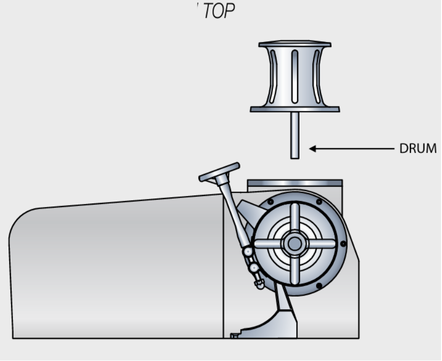

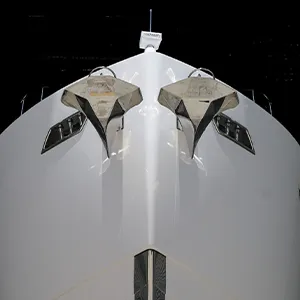

Stray current from the boat’s electrical system: If the boat’s DC electrical system is improperly grounded or if there’s a fault in the wiring, electrical current can escape into the water and pass through the anchor chain. Anchor winch faults and solenoid wiring are often the cause.

Imbalance between anodes and other metal components: If the boat has an improperly sized or positioned sacrificial anode, or if different metals (like copper or bronze) are in contact with the anchor chain, it can create a galvanic couple. This causes the electrical current to flow through the chain, promoting electrolysis.

Electromagnetic interference: Electrical systems aboard boats (including radios, sonar, and other electronics) can inadvertently create stray currents in the water. This is especially true in marina environments or locations with heavy electrical interference.

How to Mitigate the Effects of Electrolysis

While electrolysis cannot be completely avoided, there are several steps you can take to reduce its impact on your galvanized anchor chain:

1. Proper Grounding and Bonding of Electrical Systems

Ensuring that the boat’s electrical system is properly grounded including the Anchor Winch is critical. A fault in the grounding system can lead to stray currents, which increase the likelihood of electrolysis. Consult an experienced marine electrician to check your system regularly and to ensure that all components are well-bonded and grounded.

2. Regular Inspection and Maintenance

Even if your chain is galvanized, it’s important to inspect it regularly for signs of wear and tear, including damage to the zinc coating. If the coating is compromised, consider replacing the chain or re-galvanizing it. Pay special attention to areas where the chain contacts the sea bottom, as these are the most likely to experience wear. It is important to maintain the anchor chain breaking strength.

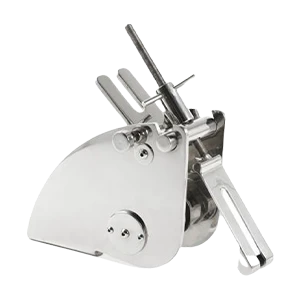

3. Use of anodes

Properly maintained sacrificial anodes, such as zinc or aluminium anodes, can help to protect your chain. Anodes work by corroding instead of the metal they are protecting (in this case, your anchor chain). However, anodes must be sized correctly and placed in the right positions to be effective.

4. Isolation of Electrical Systems

If possible, try to isolate your boat’s electrical system from the water particularly your Anchor Winch when at anchor. This can be done using isolators or special switches that ensure electrical current doesn't flow into the water. Many newer boats come with this feature, but if you’re unsure, consult with a marine electrician.

5. Use of Non-Galvanized Chains

Some boat owners may opt for stainless anchor chain, seeing it as the best anchor chain for saltwater. Other corrosion-resistant materials may be a better option than galvanized chains, particularly if the boat is frequently exposed to electrolysis or stray current issues. Stainless steel chains are less prone to galvanic corrosion but come at a higher cost.

Conclusion

Galvanized anchor chains are a good choice for many boaters. They resist corrosion and are affordable. However, electrolysis can still harm them.Stray electrical currents in the water can rapidly degrade the protective zinc coating, leadingto rust, pitting, and structural damage to the chain. By taking preventative measures—such as properly grounding electrical systems, maintaining sacrificial anodes, and conducting regular inspections—you can significantly reduce the risk of electrolysis and ensure the longevity and reliability of your anchoring system. Remember that taking proactive steps today can save you from costly replacements and potential safety issues in the future. If you're unsure about how to assess or mitigate electrolysis in your system, don't hesitate to consult with marine professionals who can provide guidance specific to your boat's setup.